PC OMR 4.7 serial key or number

PC OMR 4.7 serial key or number

ABBYY FineReader 15.0.112.2130 Crack With Serial Keygen + Activation Key Free Download

↓↓

↓↓

ABBYY FineReader 15.0.112.2130 Crack & keygen + Activation Keys Free Download For Windows and Mac [32 & 64 Bits]

Abstract : ABBYY FineReader 15.0.112.2130 Crack Serial Key scans text, layout and tables. It currently supports and recognizes 192 languages. abbyy FineReader 15…

We have all been there at a point in our lives that we need to edit a paper-based document. You cannot edit paper documents easily because they are delicate. FineReader has come to the rescue. It solves the problem of digitizing paper media is such an easy way. It scans PDF documents and a number of formats we’ll discuss later on. You may also like Microsoft Office 2019 Crack.

abbyy FineReader 15 Crack is an OCR (Optical Character Recognition) software application which has the ability to access and modify information locked inside documents that are based on paper. FineReader is a desktop application which runs on MacOS, Windows and Linux systems. It is developed by ABBYY-a Russian company and is currently licensed under the Commercial proprietary software for retail or volume licensing.

ABBYY FineReader 15 scans text, layout, and tables. It currently supports and recognizes 192 languages of the world, be it formal or artificial languages. These languages include Chinese, Afrikaans, Arabic, Kazakh and a host of other languages. This application is compatible with external scanners and cameras (digital cameras). It also detects connected devices meaning images can be uploaded from your camera or hard drive. Once the image is read, FineReader opens the original image and the digitized editable version of the image.

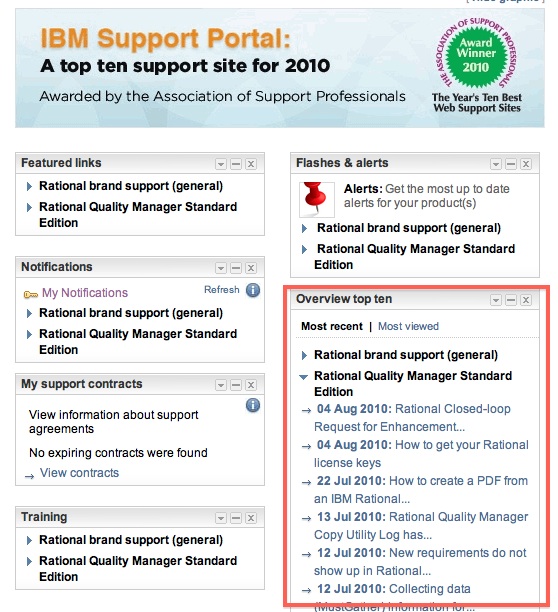

Screenshot

Features of Abbyy FineReader 15 Crack Full Version

The basic features of FineReader are, but not limited to, these.

- You can edit text, modify pictures

- gives room for arranging pages

- adding protection to documents

- adding reviews and comments

- enables form filling

Going Technical

abbyy FineReader 15 Crack Engine is used to integrate multilingual text recognition and conversion technologies into external applications. This engine gives software developers some prospects of integrating FineReader into their applications.

The application can convert PDFs and images into a large variety of other digital formats. It also reads and recognizes a large variety of sources ranging from documents with OCR machine-print text, barcodes, and check marks on reports with OMR. This is even good for examiners.

Recently, new key features have been added which includes Classification, Business Card Recognition, New and Improved OCR Technologies

System Requirements

- Operating System: Windows 7 or Higher, Server 2008 R2 or later version

- Hardware: Processor speed of at least 1 GHz

- RAM: 1 GB minimum, 4GB recommended

- Hard Disk: Minimum of 2.4GB free space

- Keyboard and mouse

- Has native 64-bit Support

– Linux users

FineReader comes with a FineReader Engine CLI.

Supported OS: Fedora, RedHat Linux, openSUSE Debian GNU/Linux, Ubuntu (16.04.1 LTS, 15.10, 14.04.5 LTS and 12.04.5 LTS) and CentOS

– Cloud Computing Platforms: Windows Azure and Amazon EC2

Supports Virtual Environments like Microsoft Hyper-V, Oracle VM VirtualBox 3, 4, Linux KVM and VMware Servers

Supported Applications

- Microsoft Word, Excel, PowerPoint, SharePoint

- Apache OpenOffice Writer

- LibreOffice Writer

- Adobe Reader

PROS and CONS

| Pros | Cons |

| Very easy to use | Images are not handled the same way a text will be handled |

| Gives Fantastic text results | |

| exports in a lot of formats | |

| fast performance | |

| supports a wide variety of language | |

| creates searchable PDFs |

Pricing

Expectedly, FineReader comes with a pricing plan. The good news about this plan is that it is a one-time purchase; meaning no renewal is required.

Below are the plans. The higher you pay the more services you get. You can also upgrade at any time.

Note: These plans are for one user. Enterprises or corporate bodies can request a quote from ABBYY.

- Standard USD 118.3

- Corporate USD 174.3

- Enterprise USD 314.3

Also note: You can get a trial version of the software which

- lasts for a period of 30 days;

- has a limit of processing 100 pages

- Can convert and export only 3 pages at a time

How to Install?

- Go to The download link to get the crack

- Fill in your email and request a download link

- Check the box underneath the email form if you want to receive updates or subscribe to FineReader’s newsletters

- Submit

- You’ll get a link in your email from ABBYY where you can get the trial version

- You can upgrade to any of the plans mentioned above when the trial period expires

How to Crack ?

On expiration of your trial version or even before, you can get the crack and thus get full access to all its features by following these simple steps:

- Download the crack here and double-click to run.

- Go to your hard drive to find the software folder

- Copy all the contents and paste them into the install directory

- Cracking is complete.

Abbyy FineReader Activation Key

- A8257FD5895E6E2B5AAF85CDACB56

- B27F5D2AD7EE6EFCF67419CB99A7C

Conclusion

ABBYY FineReader 15.0.112.2130 Crack to try out seeing it solves important problems. It has a good run for its price. Other software in its category offer less than 10 days trial period and offer less functionality when compared with it. Comparison in terms of file input and output formats, system support, and language support brings FineReader at the top of the list of OCR software. You may also like IDM Crack

CH662434A5 - Franking machine. - Google Patents

The present invention relates to a franking machine.

Electronic franking machines are known which have one or more microprocessors to control various functions and operating sequences of the franking machine. For security reasons, all data relating to bookings can be kept separate from the data relating to the other control functions. With these franking machines, it is difficult or impossible for the franking machine to be able to interface with external devices.

The aim of the invention is to provide a franking machine which allows its control power to be replaced by an external device in a simple manner, in order thereby to enable the control of the franking machine operation to be transferred essentially to an external device without a change in the system -Hardware is required.

This aim is achieved according to the invention with the characterizing features of patent claim 1.

The advantages of the invention can be seen essentially in the fact that the entire control of the franking machine and the entire information present within the franking machine can be controlled by a connection via an interface connection and that all functions which can be carried out by the franking machine can be carried out from a remote station are electrically controllable, with the exception of the purely manual functions such as switching on the power and changing the date.

Further details and advantages of the invention will become apparent from the following description and the drawings. Show it:

1 is a simplified perspective view of a franking machine,

2 shows a simplified block diagram of an embodiment of a franking machine,

3 shows a block diagram of a control unit for the franking machine,

4 shows a block diagram of a booking unit for the franking machine,

5 shows a more detailed block diagram of a preferred embodiment of the control unit for the franking machine,

6 shows a more detailed block diagram of a preferred embodiment of the booking unit for the franking machine,

7 shows a block diagram of a preferred embodiment of the printer unit for the franking machine,

8 is a timing diagram illustrating the feedback operation in the franking machine,

9 is a logical diagram illustrating the transmission from the franking machine,

10 is a logic diagram showing the transfer to the franking machine,

11 shows a set of various external devices linked to the franking machine in the so-called "Dasy Chain" mode,

12 is a coherent set of flowcharts showing the operation of the control unit.

Fig. 13 is a coherent set of flowcharts showing the operation of the printer unit, and

Fig. 14 is a coherent set of flow charts illustrating the operation of the booking unit.

1 shows a franking machine 20 which is removably attached to a base 21. In this arrangement, a slot 22 is provided between the franking machine 20 and the base 21 at the front edge thereof for inserting envelopes or the like and printing a postage fee thereon. The franking machine is equipped with a display unit 23, which has an electronic display device, and with a control panel 24. The device can be connected to the electrical network via a cable 25.

The internal structure of the franking machine can be seen in FIG. 2. The housing of the franking machine 20 is divided into compartments. The printer unit 56, which controls a printer device (not shown), is arranged in a first compartment 55.

A second compartment 57, which is preferably electromagnetically shielded, is provided within the first compartment 55. A booking unit 58 is arranged in this second compartment 57.

The booking unit is connected to external, i.e. Devices provided outside the compartment 57 are connected by optical or similar couplers 59 to prevent any damage, be it accidental or intentional, that may be caused by the effect of noise, such as overvoltages, on the printer unit. Such a coupling is of course not provided for its energy source, which likewise has a power supply 60 provided in a third compartment 61 within the compartment 55. Power is supplied to power supply 60 through a filter 62 disposed within compartment 61 to eliminate voltage changes that

Would adversely affect the printer unit. -

The housing of the franking machine 20 has a fourth

5

10th

15

20th

25th

30th

35

40

45

50

55

60

65

3rd

662434

Compartment 63. In this fourth compartment 63, a fuse 66 is provided for the franking machine. This fuse 66 is followed by a thermostat 67 and a filter 68. The thermostat prevents the application of a voltage to the franking machine if excessive temperatures occur. An insulation transformer 69 and a surge arrester 70 are provided for protection. Finally, the franking machine is supplied with power via an energy storage device 71, such as a capacitor having a large value, the capacitor 71 enabling adequate energy storage, so that the data are transferred to a power-independent memory when a power failure occurs. The drop in the voltage can be detected by a sensor 72 provided in the first compartment 55, one output signal of the sensor being directed to the booking unit for signaling a change in the mode of operation and the other output signal (which may be mechanical) blocking other functions of the Print mechanism serves.

The insulating transformer 69 is also connected to a control unit 75 of the franking machine. Furthermore, the booking unit 56 is connected to the control unit 75. The control unit 75 can also be provided outside the franking machine. The control unit comprises a keyboard, display units and the like, which are required for the operation of the franking machine.

An embodiment of the control unit 75 is shown in FIG. For structural versatility and versatility, this unit preferably includes a microprocessor 80, such as the 6500 series, which is connected via conventional data lines, control lines and address lines to a conventional RAM / ROM input / timer logic circuit 81, the read-only memory, includes addressable memories, timing controls, and input / output interface hardware. By using suitable decoders 82, a keyboard 83 can be scanned in the conventional manner, and by using suitable drivers 84, a display unit 85 can be controlled in a multiplex mode, preferably according to conventional practice. The data corresponding to the depression of each individual key on the keyboard can hereby be transmitted to processor 80 in order to form serial input / output signals on lines 86 for communication with booking unit 58. If the control unit is connected to further input / output devices, such as external display or control devices, these can be coupled to the control unit via further input / output lines 88, preferably serial communication channels and via optical couplers. The control unit can have an internal power supply and controller 89, which is connected to the voltage supply shown in FIG. 2. The functions described above by the control unit are thus functions which are not critical in the sense that a loss in the control or the content of any register contained therein does not result in a loss of fees for the postal administration or the user is. These functions have been assigned to the control unit so that the protected areas of the postage meter machine only encompass the programming of the system that must be protected. Additional functions can be effected by the control unit, just as the addition of amounts entered in succession can also be controlled by the program of the control unit, since such calculations are not essential for the protection of the postage meter machine and are not carried out within the mechanically or physically protected areas of the postage meter machine need to be. In the same way, the resettable maintenance functions can be effected by programming the control unit, since these functions are not critical with regard to the booking unit and the register itself. However, in order to record these parameters in the performance-independent memory, storage in the booking unit is desirable.

It is of course evident that further arithmetic keys can be provided in the control unit shown in FIG. 3 without great difficulty, so that the franking machine can alternatively also be used as a computer.

Alternatively, the processor can be expanded by a computer chip or the like connected to the keyboard and the display unit in order to carry out arithmetic functions.

While the control unit shown in FIG. 3 is preferably arranged directly on the franking machine as a component thereof, this control unit can obviously also be arranged spatially separated or spatially separated therefrom.

Since the serial communication used in the franking machine is dominated by information and controls relating to money, a high degree of integrity is imperative. For this purpose, serial communication is used in the franking machine, in which a transmitted bit is retransmitted by its receiver for test purposes or is sent back as an "echo". If the transmitter receives all of the signals returned as an echo satisfactorily, it can emit a pulse “no error”, thereby informing the recipient of the information that the received information is valid.

An embodiment of the booking unit is shown in FIG. 4, which is preferably surrounded by an electromagnetic shield 90. The unit has a microcomputer 91 with a power-independent memory controller 92 coupled to it. The performance-independent memory controller controls the transfer of stored data between a performance-dependent memory, which can be part of the microcomputer 91, and a performance-independent memory 93. The performance-dependent memories, such as freely addressable memories, can be operated as growing working registers, falling working registers and the like. The microcomputer also has read-only memory control for the necessary booking routines and control routines. The booking unit can also have serial interfaces in order to enable its interface connections with the printer and the control unit. The microcomputer may be, for example, an 8040 series microcomputer from Intel Corporation, Santa Clara, California and has a control circuit that is similar in nature to that described with respect to controller 75. In order to avoid disturbances of the booking unit due to accidental or deliberate electrical voltage surges, and to exclude electrical noise induced by ground loops, the microcomputer communicates with the devices located outside of compartment 57 by means of suitable couplers, through which no voltage surges are transmitted to the microcomputer can. These couplers can be, for example, opto-electronic couplers and are also preferably arranged such that they are not accessible from the outside of the franking machine. A coupler 94 can be provided for two-way communication with the control unit. Another coupler 95 can be used for the two-way comm

10th

15

20th

25th

30th

35

40

45

50

55

60

65

4th

nication with the printer unit 56 may be provided. Another coupler 96 can be provided to transmit the power failure signal to the microcomputer 91. In addition, a coupler 97 can be provided for controlling a locking element (not shown) provided in the printer, for example to mechanically lock the functions of the printer.

The power independent memory 93 in the current state of the art is preferably an MNOS memory for which no safety power source is required. However, this memory can alternatively be formed from elements that must be continuously supplied with current, in which case a control circuit can be used. The purpose of the control circuit 98 is to provide power to the MNOS memory to thereby effect its data transfer operation substantially during the power on and off. The program of the microcomputer 91 is organized in such a way that the contents of the registers of the computer units are entered into the non-performance memory as soon as any sign of a power failure occurs and that this data is stored back into the working register after the power failure.

The thermostat 67 shown in FIG. 2 interrupts the power supply for the franking machine in the case of high or low temperature operation. As a result, the franking machine is automatically set in its power failure cycle as a result of the power interruption.

In the compartment 57, a temperature sensor 99 can also be arranged with suitable circuits, not shown, coupled to it and to the microcomputer, in order to transfer data into the power-independent memory when excess temperatures occur. The booking unit can also switch off the solenoid for the blocking element in the event of overtemperature via the coupler 97. It should be noted that the blocking member is also controlled by the microcomputer 91 in such a manner that the operation of the printer is blocked in the event that an insufficient postage fee is left for a printing process, or that other printer data indicate that the printer unit is not in Operation should be.

While the couplers have been shown as separate units, it is pointed out that these units can of course also contain multiple arrangements, so that two-way communication is established in the relevant circuits. It is also noted that systems for transferring data between performance-based and performance-independent memories are well known.

5, a more detailed block diagram of a preferred embodiment of the control unit is shown. In this figure, the blocks are identified by part numbers and connectors where applicable. This unit has a type 6503 microprocessor 100 in its representation, the data and address lines of which are coupled to a type 6531 RAM / ROM input / output timer logic circuit 101 and to a type 2716 programmable read only memory or PROM 102, wherein in the PROM 102 the program for the control unit is stored. Control lines such as the interrupt line INT and the read / write line R / W can likewise be connected to the circuit 101. The circuit 101 has, as will be described, a number of connection points.

The control unit also has a keyboard 103 with the numerical keys 31 shown in FIG. 1, the display keys 35 to 40 and the switch 45 which can be actuated in three positions. This control unit also includes the

Addition key 52 and postage set key 34. All of these keys and switches are connected in a matrix to circuit 101 in a conventional manner to enable the keys and switches to be scanned in accordance with the program and thus to detect the closure of a key or switch. The eight lines PA 0 to PA 7 and four lines PB 0 to PB 3 of the circuit 101 are also connected to the seven-segment display field 104 for a multiplex display which takes place in the conventional manner. The circuit 101 is further connected to a pair of connection points PC-0, PD-0 for serial communication to that of the booking unit 58. In addition, a further pair of connection points via opto-electrical couplers 107 or 108 enable serial communication with external devices. Another output is connected to a light-emitting diode 109 in order to produce a display on the display panel that the date door is not closed. Another connector is connected to a light emitting diode 110 on the display panel to indicate 20 that operator intervention is required to release the trigger mechanism provided in the base. Finally, a further connection point PB-5 is connected to the maintenance switch 50 in order to put the functions of the franking machine in the maintenance operating state into operational readiness.

The program of the microprocessors is aimed at operating the keyboard, the display panel and the like, so that the storage of data is primarily effected in the booking unit. The program includes 30 those functions that are required for scanning the keyboard, multiplexing the display unit, formatting signals for communication with the other units and with external devices and the like, so that each new information is transmitted to the booking unit can be.

A block diagram of a preferred embodiment of the booking unit is shown in FIG. 6. The booking unit contains a microcomputer 120 of type 8039, which is connected to the control unit via opto-electrical couplers 121 and 122 and to the printer unit via opto-electrical couplers 123 and 124. In addition, a connection point P-12 of the microcomputer 120 can be connected 45 to the printer unit via an opto-electrical coupler 125 for controlling a blocking element or the like. Signals that signal a power failure are also applied to the connection point TRG of the microcomputer 120 via an opto-electrical coupler 126. It can thus be seen that all signals from and to the booking unit must be routed via opto-electrical couplers in order to ensure the electrical and physical safety or integrity of this unit. The booking unit also has a number of programmable read-only memories or PROMS 127 which are coupled to the address and data lines of the microcomputer 120 55, each PROM 127 being, for example, an erasable PROM or E-PROM of type 8755. The read-only memories are connected to an electrically changeable read-only memory (EAROM) 128, for example of the type ER 3400, which serves as a power-independent memory in the event of a power failure. The working memory for the booking unit, including the registers used to store all the operating data, is provided in the microcomputer 120, these data being fed to the electrically changeable ROM 128 at a point in time at which a power drop is detected. In order to ensure complete transmission of the data, storage capacitors can be switched on in a conventional manner in order to store an adequate energy by means of the hip sin.

5

662434

proper functioning of the circuit is ensured until the transfer of data has been effected.

A preferred block diagram of a preferred embodiment of the printer unit is shown in FIG. The printer unit has a microcomputer 130, for example of the 8748-8 type. The microcomputer is connected to the input / output devices in the printer unit via suitable buffers. The mechanical and opto-electrical sensor devices within the printer unit are of a conventional type. In this way, the microcomputer is connected to a number of opto-electrical sensors (not shown) for detecting the position setting of the printing gear train. An access authorization switch, not shown, is arranged within the printer unit and is only accessible via a door sealed by the post office. These lines of the microcomputer are also connected in such a way that the position of a timer door is detected, the timer door switch and the access authorization switch being scanned by further output signals of the microcomputer 130. The light-emitting diodes of the optical sensors are scanned at the appropriate times by means of further output signals from the microcomputer 130, and yet other output signals from the microcomputer enable the step-by-step operation of the series and numerical step motors for the printing gear train. Furthermore, the microcomputer 130 has connection points TI, P2-4 for serial communication with the booking unit. Furthermore, the blocking member output signal originating from the booking unit and a further output signal of the microcomputer 130 actuate a pair of transistors in order to excite the solenoid 153 of the blocking member, the solenoid 153 only being excited when both in the booking unit and in all prerequisites are met. As a result, no printing cycle can begin until the physical and electrical conditions within the postage meter are realized for a normal printing process.

In the RMRS embodiment, i.e. The remote-controlled franking machine reset system is set by setting the switch having the three switch positions to the "combination input" position or the "amount input" position to enter the combination or the amount into the franking machine by means of the keyboard when the display unit displays it . When you leave this switch position, the displayed value is entered in the booking unit and the display unit for the next entry is deleted. The return of the switch having the three switch positions to the operating position results in the reloading routine being carried out completely by the booking unit and the franking machine returning to normal operation, after which the reloading amount is added to the “Unused postage fees” register. The combination required for the RMRS embodiment is obtained from an RMRS data center and is a random or pseudorandom number that changes for each reloading process for security reasons.

In the MMRS embodiment of the postage meter, i.e. In the manually operated franking machine reset system, the reload operation is brought about by breaking the seal of the access authorization door and switching the access authorization switch.

In the RMRS embodiment, if an input error has occurred, the occurrence of this error is counted as an indication of an attempted forgery by the machine. If a certain number of such errors has occurred since the franking machine was last set, for example nine, the function of the machine is blocked for reloading postal charges. Under such circumstances, the postage meter can be returned to its operating state at the post office. A discussion of the means for returning the machine to its full operating state is not relevant to the invention and relates to the protection of the franking machine.

As described above, each of the three units of the postage meter has a microprocessor with a read-only memory defining a specific program, and the communication between the units is effected serially and asynchronously.

This is primarily achieved by equipping each unit with a crystal-controlled clock. Furthermore, the signals are set in such a way that their transitions are precisely controlled, which ensures that if a signal occurs, it must appear within a predetermined period of time. As a further security measure for the correctness of the communication, the bits of a signal are transmitted back to the transmitter as soon as they have been received for the purpose of an error check at the transmitter, whereby a bit "no error" can be transmitted immediately following a data message if the data is correct.

The control unit program responds to the status of the postage meter machine with respect to predetermined parameters. A register present in the microcomputer of the booking unit contains status information of the franking machines of, for example, two bites, the bits of which are displayed digitally when the triggering mechanism of the franking machine requires release, if the timer door has not been opened following the last application of the operating current, or is currently open when there is insufficient funds available to allow printing of the amount set in the print engine, when the lower postage has been reached, when the postage meter is in a maintenance state, when the postage meter is ready, when the stack registers are cleared are when a trigger is complete or when different types of errors have occurred. The status message associated with these bits does not match the diagnostic message mentioned above, which is used in maintenance operation. The booking unit keeps the control unit informed of the current status by transmitting the status message to the control unit after the power has been switched on and then whenever a change in status occurs, the control unit responding to all such messages by it ensures that the franking machine display is consistent with the status message discussed above. These last-mentioned steps can include, for example, the display of a line of decimal digits when certain errors occur, as well as a flashing operation of the decimal point when the lower middle postage limit occurs, a flashing operation of the entire display unit when an insufficient postage fee occurs, the display of underlines instead of spaces if the Postage meter machine is in the maintenance state. An interruption program provided in the control unit interrupts the main program of the control unit at regular intervals in order to scan the keyboard and the key switch and to control the display unit. In order to prevent the display unit from appearing signs that can be generated by unwanted shunt currents when more than one button is pressed, this causes

5

10th

15

20th

25th

30th

35

40

45

50

55

60

65

UUX. HM

6

Interrupt program instead a blank display of the display unit. The inventory of values related to time, keyboard and key switch is done by the interrupt program for use by the main control program.

The main program for the control unit includes initial value setting steps, program steps for the two-way transmission of messages between the booking unit and external devices and for control of the time-controlled display unit, a check of the status message to ensure that the date generator door and the reset base lights accordingly status lit, responsive to the notified switch positions and the three position switch to ensure state changes occurring therein so that the control unit subroutine corresponding to the function defined for such a state or change of state is executed.

The booking unit's program has initial value setting procedures to ensure that the working registers are updated and that no postage fee that has not been booked has been printed, and a power outage processing program to convert the data transfer into a non-performance (electrical changeable) memory if the power breaks down or fails.

The main program of the booking unit effects the transmission of the status message of the franking machine to the control unit on command or upon a change of the status, detects the effect of each currently entered postage value on the currently registered data about the fee means and carries out all necessary changes of the status message. The main program also controls the timing in the booking unit for receiving messages from the control unit and the printer. The program of the booking unit also has subroutines for processing signals, by means of which the registers can be updated when a postage fee is to be printed and by which the operating sequence of the system is controlled when the franking machine is triggered. Another subroutine is used to update the status message of the franking machine. In addition, an error check routine is programmed into the software of the booking unit, which carries out a cyclical redundancy check. This is described in detail below.

The program of the printer unit has a main program with steps for initial value setting, steps for scanning the sensors and controlling the scanning for the light-emitting diodes of the sensors as well as the processing of messages for communication with the booking unit. Subroutines are provided to adjust the postage fee print engine to determine if sensor readings are correct and to determine if there have been any changes in the outputs of the various hardware sensors and switches such as the access switch and the timer door switch.

With regard to the program for setting the display unlock value described above, the adjustable maximum amount and the lower postage fee amount, the keys causing such setting are arranged in the keyboard in the manner described above as a matrix and are periodically scanned to determine whether the status has changed. The scan position also occurs opposite the maintenance switch in the control unit, whereby the control of each key and switch is communicated to the booking unit for storage and processing. If, for example, the maintenance switch is set to its "on" position, the scanning, which is also effective with regard to the switch having the three switch positions, sets a combination input routine or amount input routine as a display routine, depending on the position of the switch having the three switch positions in 10 operational readiness.

The display subroutine sends the data available in a register corresponding to a pressed display key to the control unit for display. In the combination input subroutine, the next entry made on the keyboard is stored, so that the value entered on the keyboard is entered into the corresponding register of the CPU of the booking unit in the event that the switch having the three switch positions has been turned into an amount input position, whereby the value entered in this way will take effect in the normal operating procedures when the machine is to be operated in the future. Of course, it is clear that the set values are checked effectively in normal operation with regard to a range of values, for example a range of 25 postage fees that are smaller or larger than the stored amount, so that the necessary notification can be given. The term “display” as used in this sense refers to the display unit. If the entered postage value exceeds the maximum settable amount, the entered value is skipped and the display returns to its original postage value. The maintenance adjustable properties as disclosed above can also be considered to serve to control the postage meter in 35 different states, such as an ineffective state when the maximum adjustable amount has been exceeded, a lower limit warning state when the lower limit display flashes and a lock value condition requiring an additional press of the setting key if the amount set in the display exceeds this stored value.

In terms of system diagnostics, to which reference was made briefly above, two basic error checks are provided in the software routine of the postage meter machine. These two error checks are termed fatal or procedural. Two subcategories are defined within the category of fatal error checks. These two subcategories are referred to as hard or soft, so the detection of hard errors is carried out by monitoring hardware sensors, such as group dial and digit dial sensors, switch position sensors, cross bar sensors and the like. A failure of correct reading values generated by these sensors is called a fatal hard error 55, which locks the charging machine and which cannot be remedied after the power has been switched on. The intervention of a central authority is then required to enable the franking machine to continue operating.

60 Another example of a fatal hard error is a resulting non-comparison from a cyclical redundancy check. Each data register is continuously monitored. Using standard polynomial techniques, a cyclic redundancy remainder is calculated for every 65 updated data register values. When a power failure cycle is initiated, the content of each data register and its associated cyclical redundancy remainder become independent of performance

7

662434

current memory. When the power is switched on, the cyclic redundancy remainder of each data register is recalculated and compared with the cyclic remainder previously calculated when the power is switched off. A non-comparison creates a fatal hard error.

Fatal soft errors relate to the inter-communication properties of the franking machine units. Communication errors between internal units such as the booking, printer and control unit are recorded on the basis of the bit retransmission described earlier. In addition, communication time output functions are provided so that the lack of communication of a unit within a certain period of time also creates a soft, fatal error. Soft, fatal errors block the operation of the franking machine. A release can be brought about by a cyclical return of the franking machine; i.e. that the franking machine must be switched off and then switched on again, which brings about the cyclical feedback and deletion of the error. The cyclical feedback of the power supply is counted in a data register and, if desired, can cause a total lock when a predetermined number is reached. In other words, a predetermined number of soft fatal errors equals one hard fatal error.

Procedure-related errors, such as incorrect (too high) value entries or the attempt at an incorrect procedure are expressed as visual marks on the display unit.

Further diagnostic tests, as well as modifications, as discussed above, can easily be fitted into the software routines implemented herein.

By serially communicating the data between the units on the basis of messages and using the above-described "echo" technique, the implementation of the above-described error checking properties can easily be achieved.

As explained above, the communication between the microprocessors or microcomputers of the units takes place from a bit-synchronous, character-asynchronous start / stop communication taking place in a serial channel and can take place, for example, at 9,600 baud. Communication is based exclusively on messages, i.e. that separate control lines between the microprocessors or microcomputers for controlling the communication are not provided. The length of the messages is 10 bits, each of which has a start bit and a subsequent eight-bit word or byte and is terminated with a stop bit. The meaning of the last stop bit of a message is opposite to all other stop bits of the message to indicate the end of the message. A logical zero indicates a start bit, a message end bit and a zero date or a low value. A logical one is provided for a request to send, a readiness to send, an end of byte, a data level «1» and also for the presence of an error-free pulse. The first word of each message has an encoded two-bit field that determines whether the message contains information, data, or control functions. Another bit of the first word indicates whether the message only affects the display unit or not, or whether it only affects the booking unit. The rest of the bits of the first word form specific message identification bits.

If the messages consist of more than one word, the second word of the message may have a format byte consisting of two nibbles, i.e. Four-bit groups. The first word of each message has an encoded two-bit field that determines whether the message contains information, data, or control functions. Another bit of the first word indicates whether the message only affects the display unit or not, or whether it only affects the booking unit. The rest of the bits of the first word form specific message identification bits.

If the messages have more than one word, the second word of the message may contain a format byte consisting of two nibbles, i.e. There are four bit groups. The first nibble specifies the number of data nibbles in the message, and the second nibble specifies the number of digits to the right of the decimal point of the data or corresponds to a hexadecimal F if there is no decimal point.

If a message is provided for transmission in a unit, the reception line of the unit is checked first. If it is at a low level, the transmitting device raises a transmission line to a high level and checks the reception line again. If this is still at a low level, the unit is released for transmission, otherwise it must assume the role of a receiver. This avoids controversy between two units. With regard to units of the franking machine itself, the programs of the various units give the priority of the printer unit, booking unit, control unit or the external device in the event of a possible controversy in descending order. If the franking machine, i.e. external devices are connected to the control unit, the control unit is given priority.

Message timing control is the most difficult communication problem, and messages can be asynchronous. A typical timing is therefore shown in Fig. 10, which shows the relative timing of the lines of the transmitter for sending a given message and the lines of a receiver for receiving that message. Since the output line of the transmitter matches the input line of the receiver, it is clear that these two signal lines are identical. The same naturally applies to the input line of the transmitter and the output line of the receiver.

Upon successful transmission in such a system, the transmitter checks its input line at time ti and, if a low level is found, raises its output line to a high level within 50 microseconds, as shown at ti. The transmitter then checks its input line again within 50 to 100 microseconds at time t3. If the input line is still low, the transmitter can begin sending its message after a minimum waiting time of 120 microseconds at a time ts by lowering this output line to low to form the beginning bit of the message. In the meantime, at time t-t, the receiver has raised its output line to a high level within a minimum time of 100 microseconds, which indicates that it is ready to receive data. This indicates a «ready to send» status. The time between successive bytes of a multibyte message, indicated by the time interval between ts and t's, is at least 1134.375 to ensure that the receiver is ready to perform correct reception and storage of the signals.

The time between the beginning ts of the last message bit and the transmission of a pulse "error-free" at time t is between 1031.25 and 1157.291 microseconds.

5

10th

15

20th

25th

30th

35

40

45

50

55

A0

65

OOZ434

represents, and the pulse "error-free" has a width of. 309.375 microseconds to 368.228 microseconds. The receiver must check for the occurrence of an "error-free" pulse at time ts between 1187.291 to 1340.625 microseconds after the initiation of the start pulse of the last byte of the message. The transmitter bit transitions must be in accordance with Table I and the receiver sampling of the data and stop bits must be in accordance with the timing shown in Table II.

Table I

n

BIT

minimum

Maximum i

Start o

O

2nd

Dates 1

103.125

105.208

3rd

Dates 2

206,250

210.417

4th

Dates 3

309.375

315.625

5

Dates 4

412,500

420.833

6

Data 5

515.625

526,042

7

Dates 6

618.750

631,250

8th

Dates 7

721.875

736,458

9

Dates 8

825,000

841,667

10th

stop

928.125

946.875

Table!!

n

BIT

minimum

1

begin

2nd

Dl

115.208

3rd

D 2

220.416

4th

D3

325.624

5

D4

430.832

6

D 5

536,040

7

D 6

641,248

8th

D7

746,456

9

D 8

851.664

10th

stop

956.872

Asynchronous transmission can be carried out by the above timing and by crystal control of the clocks of each unit, so that control lines between the units are unnecessary for this purpose.

To ensure that the information is correctly received by the receiver without errors, the data is sequentially transmitted back to the transmitter on the receiver output line. The times for retransmission of the data are given in Table III from the beginning of the instruction loop for acquiring the start bits, and the times for sampling this data on the input line for the transmitter are given in Table IV.

The "error-free" pulse is only transmitted at the end of the message if the data received by the sender match the data sent.

For further control over message communication, the sender waits for a transmission ready signal of the receiver for 3.5 milliseconds after issuing a transmission request, and likewise the receiver waits for a maximum of approximately 3.5 milliseconds for the start of a message after it has finished transmitting. has issued a company message. Conversation between the units is further reduced to a minimum by the fact that certain time intervals can be set that must exist between adjacent transmission activities of a unit and also between adjacent receivers.

Table III

n

BIT

minimum

maximum

1

begin

32,083

73.125

2nd

D 1

137.292

176.250

3rd

D 2

242,500

279.375

4th

D3

347.708

382,500

5

D4

452,917

485.625

6

D 5

558.125

588.750

7

D6

663.333

691.875

8th

D 7

768,542

795,000

9

D 8

873.750

898.125

10th

stop

978.958

1001,250

* Allows 10 microseconds for program loop uncertainty when capturing the start pulse. If the uncertainty is greater than 10 | isec, the excess must be subtracted from each maximum value.

Table IV

n

BIT

minimum

Maximum i

begin

103.125

135.208

2nd

Dl

206,250

240.416

3rd

D 2

309.375

345.625

4th

D 3

412,500

450.833

5

D 4

515.625

556,041

6

D 5

618.750

661,250

7

D6

721.875

766,458

8th

D7

825,000

871.667

9

D 8

928.125

976.875

10th

stop

1031,250

1082,083

All control and data signals use the same pair of conductors in each direction with a precisely defined timing for control purposes.

In order to create an external control, the control flow runs in one direction and the information flow in the other direction.

The entire control of the franking machine and all of the information present within the franking machine can be controlled via an interface connection device along the lines 88 of FIG. 3. All functions performed by the franking machine can be controlled electrically from a remote station, with the exception of purely local manual functions, such as switching on the power and changing the date. This results from the communication capability of the data units. The software routine scans for the presence of an external control device and enables the transfer of control to such an external control device after recognition of its validity. The organization of the three units results in a flow of commands or control of data from the control unit to the booking unit and then to the printer unit. An example of such data and commands is a new postage fee and where it needs to be set. The flow of information takes place in the opposite direction. An example of this is an instantaneous register value or the like. With this concept, it is by turning on an external device, such as a

8th

s

10th

15

20th

25th

30th

35

40

45

50

55

60

65

9

662434

electronic scale, in the control unit possible to insert commands or data control command information into the franking machine. The interface operation enables the external device to control the postage meter, including decommissioning the keyboard of the control unit if desired. The external device is connected to the franking machine on the basis of messages. The external device may send messages for display purposes or may send messages requesting the content of the display unit. The programming of the control unit enables the external device to send a message decommissioning the keyboard, which implements the transfer function. A particular advantage of the above arrangement is that the control unit can be replaced by an external operating device added, without requiring any changes in the booking unit or the printer unit, neither in the hardware nor in the software.

The control unit microprocessor can be used to act as a message buffer to allow flexibility in the design and use of external devices. The external devices can include weighing devices, display units, or other types of devices normally interacting with postage meters of the type disclosed herein. The software provided in the control unit can be implemented for this function. As shown in FIG. 9, an external device 150 can be used to replace or supplement the function of the control unit. The external device 150 is preferably connected to the control unit via a line 152 and a plug connection, which can be formed by a standard nine-pole plug connection. 154 of the franking machine is connected and receives messages from the franking machine unit 156, which comprises the booking unit and the printer unit. The control unit has communication buffers 158, by means of which the communication from the franking machine unit 156 is directed to the external device 150 or locally to the control unit 154 from a logical point of view. The reverse effect is shown in Fig. 10, in which external devices can communicate with the unit via the communication buffers. The effect is the same in that the buffer receives messages either from the external device 150 or locally from the control unit 154.

FIG. 11 shows a number of external devices 164 which are coupled into the franking machine unit by means of the control unit 154. Each external unit can be provided with its own control button for initiating messages. Each external device could contain a communication buffer as part of its software in order to enable the external devices to be operated in dasy chain mode. Appropriate messages may include complete submission of the control unit to the external device. The control unit programming is designed in such a way that such operation is possible.

With regard to the operation of the external devices, the information flows in two directions, either inwards into the franking machine or outwards to the external device. Control signals and prompts, which are generally defined as controls, flow inward into the franking machine. Information data flows abroad. The control commands on the inward line normally come from the control unit. However, it is also possible for an external device 150 to issue commands directly through the control unit to the franking machine unit. Conversely, information data on the outward line from the franking machine unit 156 (booking unit) arrive at the control unit 154 and are repeated on the line 152 for the external devices for forwarding to the external device 150, provided an external device 5 is present. The presence of an external device 150 is determined by detecting whether it is responding to a ready-to-send signal or not. If this is not the case, the output signal on line 152 turns off after a preset period of time (blocking time) and the franking machine continues its normal operation. This ability to send information through the communication buffer in the control unit enables the advantage of attaching external devices to it. The external device can be constructed in the same way with a communication buffer as shown in the control unit, and such a device can in turn have an external device coupled to it. In this way, a chain of external devices 164 called a daisy chain, as shown in FIG. 12, can be created. The only 20 limit to the number of external devices that can be daisy-chained to them is based on system tolerance and lockout time restrictions.

Furthermore, it is provided that external devices issue certain commands to the control unit itself, these commands not necessarily being issued to the booking unit, such as the ability to write out a message on the display unit of the control unit, or to read a message from the display unit of the control unit, or to give the control unit a command to decommission its keyboard and the rotary switch having the three-switch position. In this process, the communication buffer responds to a bit in the initial part or the header information of the digitally transmitted message sequence and indicates the direction whether the message should reach the franking machine unit or the control unit. This bit, which has a specific position in the header as described above, is assigned a "1" in this position if it is a message from or to the control unit, and a "0" if it is a question a message to or from the franking machine unit. In this way, the control unit can check the header information when the external device receives a message and determine from this bit whether the message is intended for the control unit or for the booking unit. If it is intended for the control unit, it stops the message and carries out the corresponding activity. If it is not intended for the control unit, “the message is forwarded to the franking machine unit.

50. .

headed.

The control unit can provide an immediate response to the external device without even bringing the franking machine unit into play, for example in response to receiving a message related to reading the display unit. The last received franking machine status message is not stored in the control unit. Therefore, if, for example, a command to take the keyboard out of service is received, the control unit requests a franking machine status message from the booking unit. When the control unit receives the response, it inserts a bit in the franking machine status message to indicate whether the keyboard is operational. When the shutdown is complete, the control unit continuously displays the shutdown status in the status message until a reset is received by receiving a keyboard startup command or until the power is turned off and on. When entering

00 ^ 4J4

10th

When the power is switched on, the keyboard is always in the commissioning state.

The franking machine is therefore able to interface directly with the external devices, which is difficult or impossible with known franking machines.

In summary of the above, it can be seen that the control unit is provided with a plug connection for bidirectional communication with a number of external devices. This enables the external devices to access franking machine information such as register read values, number of pieces and selection of current values. In addition, the franking machine can be controlled by an external device to the same extent as the operator can from the keyboard.

The franking machine can be provided with an additional device in order to automatically record and reload postage fees for various departments on the basis of identification information entered by the operator at the start of each franking run. The franking machine can be used together with a display unit / receipt printer, whereby the customer can be served with a visual display of the value present on the franking machine and / or a receipt for paying the postage fee. The franking machine can be used together with the customer's own

Devices such as a computer terminal or a minicomputer system for real-time data acquisition are used, as is the case in packet processing when the postage fee is added to the recipient address.

s The relative simplicity of the interface-based coupling of the franking machine suggests further possibilities. Two examples of this are 1) the use at the end of a deciding one-key device to change postage fees with a variable number of keyings to 2, 2) as a practical mailing machine.

Flow charts illustrating the operational flow of the various units are shown in Figs. 12, 13 and 14. In all cases, the figure numbered without letters shows how the figures with the corresponding numbers and 15 letters are to be put together in order to obtain the complete flow diagram.

The flowchart representing the operating sequence of the control unit results from the sequence according to FIG. 12.

The flowchart representing the operational sequence of the printer unit results from the sequence according to FIG. 13. The flowchart representing the operational sequence of the booking unit results from the sequence according to FIG.

The programmed functions result from the detailed expression for the booking unit, control unit and printer unit, which are attached as an appendix to the preceding description.

37 sheets of drawings

fi 5 00 ACCOUNT IMG MODULE CAflûM / ll vei.fi ioti <1.21.! i 7 l5-Oct-79 1 2: 4 6:53 TABLES FOR BIJCIIIJNGSMODUL UNO R AM-fì PEI Cll ERTA BELLE | DM2.-PEPACC.SftC

2nd

3 NLIST

7 LIST

8th

9 3Û 1 1 I 2

13.

14. 6 5 0 0 NUCTION MODULE I 5

16

17th

, B COPYRIGHT 1979 PITNEY BOWES INCORPORATED

19th

20 2)

22

23 INCLUDE DMOiACCTBL

24 'NLIST

64 "-» ST

65 ™ Gli:

6500 cao n 4 0/11 version 4.21.57 15-Oct-79 12: 4 7 î 50

tables for bucnuhgsmonijl uno r am-spinclllîrtabttllr

66

67 60

69

70

R A M - S P1:

ÄTC'lIRRTABISLLE

PURE LETSTUNGSNÄSSnXNIGENICHER MEMORY

71

72

73

0020

PECEKT

EQU

20th

0 digits number of pieces

74

0024

dscecc

EQU

PECEKT

♦ PECEs a

1 Hyr.ß CRC for descending register

75

0025

DSCREG

EQU

dscêcc t DSERSZ

0 digit descending register (usable postage fee)

76

0029

ASCECC

EQU

dscreg t DSCRSZ

1 byte CRC for growing register

77 70

002A 0 0 2 P

ASCREG PRSTAT

EQU EQU

ASCECC »ASCREG

ASERSZ t ASCRS2

10-digit register (cumulative 1 byte printer status postage fee)

7 9

0030

POSVAL

EQU

PRSTAT

t PRSTS Z.

fi digits postage

00

0033

batamt

EQU

POSVAL

»POSTS Z

fl digits stack amount

01

0037

BATCHT

EQU

BATAHT

t BATASZ

fi digits stack number

02 0.1

0 0 3A

HOM VOI,

date ciiecksiim POR equ IJATCHT

BLOCK 0 «I1ATCSZ

Next RMRS (remote-controlled) COMBO (combination), which is available in part ml. Le

04

003C

t'OHECC

EQU

DATE t

DATES '/

1 ByLu CRC for checksum

115

• 003D

RSTVAR

equ

CÛIIECC

i 1

RMRiì machine settings 1 l value

06

004 1

RSTCIIT

EQU

RSTVAR

i IISTVS2

1 llyte to count unsuccessful new attempts

07

0042

PATCÛD

equ rstciit •

• 1

1 byte for storing code, the fatal errors:

00

004 3

FATCHT

EQU

PATCOD

t 1

2 digits fatal error counter sentenced

09

004 4

MTRTYP

EQU

PATCMT

" 1

1 byte for machine type: 0 = manual, 1 = RMRS

6500 ACCOUNTING MODULE CA0040 / 11 version 4.21.57 15-ÛCL-79

1 2: 4 7: 5 nights

90

0045

MSBRNO

EQU

MTRTYP *

1

91

004 9

UMI.OCK

EQU

MSERNO t

M'SERSZ

92

00 4C

LOWPOS

EQU

Uli LOG.K t

UIILVS2

93

00 4 E.

SETI. r M

EQU

LOWPOS t

I.W PS S Z

94

0050

RSTIIAS

EQU

S ETI, IM *

S ETI, S Z

95

'C1IRCKSUM

POR

BI.OCK 1

9 6

0054

TI MCNT

EQU

RSTBAS t

RSTBSZ

97

0055

T I MWIIO

EQU

T1 MCNT »

1

9 Q

0056

MRSTAT

EQU

TI MWIIO «■

1

99

0056

STATE

EQU

MRSTAT ♦

2nd

100

0059

ACTßl.K

EQU

STATE »

1

101

00 5A

M Vl-lli I.K

EQU

ACTßl.K ♦

1

1Û 2

Û05B

CNTXPL

EQU

MVMßLK *

1

103

005C

RECüPL

EQU

CNTXPL *

1

104

005D

P01.CMT

EQU

RECO PI, t

1

1 05

005R

RECHUP

EQU

POI.CNT »

1

1 06

0066

wrkbpi

EQU

RECßUP t

RECßSZ

1Û7

006R

WHERE L 1.1 K

EQU

WRKBP1 »

WRKlisZ

1 00

00 7 6

AMTßP

EQU

WORKBP •

WRKRSZ

109

00 7 n

C HIÎO HP

EQU

AMT IIP »

AMTSZ

110

00 7 P.

I.AST

RQU

cmboßp i cmbos2

1 l-l

1 1 2

StJBTTl. HEADER

ASSIGN

1 1 3

PAGE

7 digits for serial number 6-digit field for unlocking value 4-digit field for lower portfolios renwa renwe r i 4-digit field for adjustable postage-manual combination

1 byte for timer counter

upper limit

2 bytes for maintenance of the machine status

1 byte for operating status or type

1 byte to indicate which block is currently open

1 byte to identify the deleted section of the non-performance memory (NVM)

I byte for queue status message to control unit

Control unit receipt brand

(0 = • no message waiting to be processed) Message printer receive mark (0 = no waiting to be processed

0-byte buffer for receiving messages ft-byte working buffer second. O-byte work buffer

Amount entry buffer

Buffer for combination input last used RAM memory space

>

0 \ 0 \ s »

6500 ACCÛIJNTING MODULE CA / 104 0/1 1 HEADER ASSIGMMFNTS ACCTBL.SRC 1 1 4 115 1 1 6 1 1 7 110 l 1 9

120

121

122

123

124 1 25

version 4.21.57 15 ~ Oct ~ 79 12:47:50

34

35

IIBAHBR ASSIGNMENTS

MMEMOHIC VALUE Mnemonic code value

COMMANDS NO DATA

Description commands without data

26

0040

NODATA

EQU

40

27th

004 1

ENQLIID

EQU

4 1

Release machine command

20th

0042

DSBLIID

EQU

42

Lock machine command

29

00 4 3

ENDEIID

EQU

43

End of entry

30th

0044

CLRBIID

EQU

44

Delete batch command

31

0045

ACMPIID

EQU

45

Booking complete

32

0046

SETSIID

EQU

4 6

Setee maintenance condition

33

Q0 4 7

CLIÌSIID

EQU

47

Clear maintenance status flOMMANDS WTTII DATA

Commands with data

6500 ACCOUNTING MOIMJLB CA 0040 / U version 4 HEADER ASS IGNMENTS ACCTBL.SRC

137

noco

WTIIDAT

EQU

OCO

130

00C1

SPOSIID

EQU

0C1

139

SAVE

EQU

0C 2

140

SAVE

EQU

0C3

141

00C4

SDATilD

EQIJ

OC 4

142

ÛÛC5

ENTAIID

EQU

0C5

143

0ÛC6

ENTCIID

EQIJ

no

144

145

REQUEST

VALUE

146

147

0050

REQVIID

EQU

50

140

OOOO

VLI SIID

EQU

'000

149

150

ITEMS REQUESTABLB

151

152

0000

STATNB

EQU

000

153

000 1

POS VII B

EQU

001

154

VA LUID

STANDARD

155

OXXX

156

2nd

ASC

REG / waxing reg.

157

3rd

DSC

REG / abfal1 end.Reg

150

4 CONTROL

SUM / Controi 1 sum

21.57 15-Oct-79 '12:47:50

Set postage fee

Set the date

Enter new setting amount Enter new setting combination

Request value

>

Request value Lower NIBBLE returns ^

Value displayed on request

Required items

Postage fee maintenance

Unlock value lower limit for postage fee machine number

6500 ACCOUNT I MG MODULE CA (1040/11 HEADER ASSÏGNKENTS ACCTRL.SRC

version 4.21.57 15-Oct-79 12:47:50

159 1 60

161

162

163

164 1 65

5 PEICE CQUNT / quantity fi BATCH AMT / batch amount

7 BATCH COUNT / number of stacks

SUflTTI. STATUS ASSIGHMENTS PAGE

Diagnostic status

Adjustable postage fee limit free

Congestion allocations

6500 ACCOUNT! NG MODUI.B CAQQ40 / 11 vareion 4.21.57 15-0cl-79 STATUS ASSIGNMENTS ACCTBL.SRC

166

167

LESS3 STATUS ASSIGNMENTS

169 1 70

171

172 BIT DESCRIPTION DESCRIPTION 1 73

174 PRINTER / PRINTER

1 75 7 PRIV ACCESS SW / access control switch

1 76 6 DATER DOOR / Datemnsgeliertiir

1 77 5 SIIUTTER BAR / bar

1 7 0 4 I.AST HOHE / Auagangsstel 1 ung

179

TRIP (NOT IIOME) ^ (not starting position) 181 2 INTERPOSER POSITION / Verinittlurstellung

1Q 2 1 SAVE / 'Free

1 03 0 HARD ERROR / hard absence:

184

105 CONTROL (METER) STATUS / Steuer (machine) status

106 'FIRST WORD / First word

187 1 RESET BASE

12:47:50

1 = selected

1 = open, 0 = closed

1 = front, 0 = starting position

1 = from or in position 2

0 = from or in position 1

1 = triggered

1 = released (in operation)

1 = fatal mistake, continuation impossible

1 = base must be reset

OS © \ Kl

£

6500 ACCOUNT IWÌ MODULE CAflO <in / ll version 4.21.57 l5-Oct-79 1 2:47:50 TATUS ASSI GIIMENTS ACCTBL.SHC

opened since S t rome inselvi U. m v

1 OH fi CHECK DATE '/ date check 1 = door open or not, oo-

109 5 IH SU F F I c IENT FUNDS / 1 = abfall.Reg. <Postage value

1 90 4 I.OW POS DAY fi / lower postage 1 = waste. Reg. <Lower postage

191 3 SERVICE with OB / maintenance status 1 = maintenance

1 92 2 BNABLGD / In operation 1 = put into operation

193 1 BATCH CLEAR / batch delete 1 = batch amount and number = 0

194 0 TRIP / trip

195 SECOND WORO / Second Word

1 96 7 HARD (FATAL) I2RROR. hard (fatal) mistake

1 97 6 SAVE / Free

19 0 5 SAVE / Free

199 4 SAVING / Free

200 3 SPARB / Free

201 2 SAVING / Free

2Û2 1 SOFT BRROR / soft 'error curable error

203 • 0 SAVE / Free

204

205 METER HOPE (STATE) / machine condition

206 ALL 0 / All NORMAL OPERATION normal operation 2Ó7 7 TRIP / trip

20fl 6 ENABLB / Bel: r i ebsselvzung

209 5 DISABLß / Decommissioning

TIME! VALUES TRPSET EQU with TRPTOL EQU 163

65ÛÛ ACCÛIJHTTNG MODULE CA004Q / n ASSIGNMENT TABLE ACCTBL.SRC 2 1 Û

219

220

221

222 2 2 3

224

225

226 64064

227 0ÛA3

228

229

230

231 OÛFF CRC I ML

232 009B CRCPLY 2 3 3 '

234

235

236

237

2 3 Û Oûûl PRTEAT EQU 1 239 0002 PROFAT EQU 2

version 4.21.57 15-Oct-79 allocation s ta ha 1.1. e

Allocation table

12:47:50

CRC ASS IG NMRNTS / assignments EQU OFF EQU 9B

Time values for triggering activity 2 sec. Blocking time

Residue + <- no carry ok, C = 1 overspeed residual <93, counts

Initial value for CRC calculation CRC generation polynomial

Fatal error codes for booking-recorded errors FATAL ERROR CODES POR ACCOUNT! HG DETECTED FAILURES

Printer communication dead invalid header or software error

6500 ACCOUNT IMG MODULE CA004H / 11 version 4.21.57 15-Oct-79 12:47:50 ASS IGNMENT TABLE ACCTBL. S HC

240

0003

COMPAT

EQU

3rd

Blocking line: during communication (printer or Stouo.nin

241

0004

INTPAT

IÏQU

4th

ACC Interposer line shorted

242

0005

NOMPAT

EQU

5

Loss of synchronization in initial positions

243

0006

ECU PAT

EQU

6

Echo error during transmission

244

0007

SETPAT

EQU

7

> 2 seconds on postage setting

245

000Û

TRPPAT

EQU

0

Upper or lower speed when triggered (14 {kms TRIP

246

247

oooo

IlSTTft y

EQU

9

no successful readjustment in 9- ^ S '"k"

subsequent attempts

240

SU BT

TL

Interruption vectors

249

PAGE

6500 ACCOUNT IMG MODULE C A 0 0 4 (1/1 1 vers l.on 4. 21. 5 7 15-Oct-79 12:47:50 INTERUPT VECTORS PEPACC. SRC

250

251

Break vectors

252

INTERRUPT VECTORS

253

254

255

256

POWER

UP

S1: rome i n s eh a 11 u n g

257

0000

ORG

0

250

OQÛO

04

OE

»TMP

PWRUP

259

260

POWER

PAILURE

SI: roma u fall

261

0003

ORG

3rd

262

0003

65

STOP

TCNT

263

0004

04

09

il M P

PWRDN

264

265

TIMER

INTERRUPT timer interruption

266

000?

ORG

7

26 7

0007

Ûé

24th

JMP

TIMINT

2 6.0

260

1 NCLUDE

DMOi PWRDN

2 7.0

SUIÌTTL

POWER DOWN

271

PAGE

6500 ACCOUNT ING MODULE OA004 0/1 I version 4.21.57 15-Oct-79. 12:47:50 POWER DOWN PWRDN.SRC

272

273

274

POWER CURRENT AND POWER FAILURE POWER DOWl / AND POWER FAILURE

275

276

277

278

Store variables in performance-independent sepicher (NVM), lock centimeter (CPU). In reset state STORE VARIABLES IN NVM, LOCK CPU IN RESET MODE.

279

200

0009

1 5

PWRDN

DIS

1

20 1

00ÛA

F 4

OE

CALL

NVMWR

Write in NVM

202

000c

OA

40

ORL

P2. IK0

Enable 8755 in reset and turn off NVM

203

2 8 4

0Q0R

06

OE

PWRUP

JNI

%

Waiting for power cut to clear

285

0010

27th

CLR

A

206

0011

D7

MOV

PSW, A

207

001 2

9 A

ÛP

AHI.

P2, HOF

Clear 0755 reset, turn on NVM

200

C 1.12 AR

R.A.M.

209

001 4

IUI

20th

MOV

RO, 1 PECECT

290

001 6

l'I A

60

MOV

R2, linO-PECEKT

291

292 290

00 1 0

001 A

F 4 IUI

Eli 56

SET IM

CALL IIÏI AL MOV

CI.RIÌLK METER STATUS RO, BMRSTAT

m piiprw nîiTP Set initial machines IE CHECK DATE - atatuS / d> h <Daumsprü f t.nq

294

001C

no co

MOV

@ RO, Ï0C0

6 5 00 ACCOUNT IMG

MODU! , 12th

CAO 0 4 0/1 1

version 4.21.57 15-OCL-79 12:47:50

POWER DOWN PWRDN

.SRC

295

LOAD NVM

296

00 1 E

F 4

61

CALL

NVMRD

297

0020

C6

2 4

.lZ

PWIUIPO reading ok?

29 8

0022

9 4

ÇA

CALL

NVMPAT set fatal condition

299

0024

54

CA.

PWRUPO CAI, I,

ASCCUC '

300

0026

F 5

SRL

H lì 1 current switch in upper 2 K

301

0027

E4

A4

JHP

PWRUPA

302

3Û?

INCLUDI2 DHOiCTXnYT

30 4

'SUßTTL TRANSMIT ONR I1YTR - transfer 1 byte

305

PAGß

6500 ACCOUNT ING MODULE CA004fl / U vers i on 4. 21:57 15-Oci: -? 9 12:47:50 TRANSMIT ONE BYTE CTXBYT.SRC

306

307

300 TRANSMIT BYTE WITH ECIIO TEST

309

310

311

Hherhragalft bits (1 Stari: + fl data + 1 stop), receptacle echo, and

312 TRANSMIT 10 n [TS

SET ERROR IP NOT EXACT MATCH - set errors if not exactly right

314 NOTE: INTERNAI. T.OfiTC LEVEL REQUIRES INVERSION FOR TRANSMIT FUNCTION

• j j 5 Attention: Learning logic level requires inversion for transfer function

316 -OM a = »Error count during transmission

317 1-M RO = address of data byte 310 —M R3 - R7

319 1-- Fl = unit

320 0 control

321 1 printer

322 1-- C = stop bit level

323 0 End of message

324 1 end of Byiie

325

326 0029 27 CTXBYT Cr.R A

327 0Û2A AC MOV R4. A Clear error counter

6500 ACCOUNTIMG MODULE CA004f) / ll version 4.

with one byte

ctxßyt.src

3 28

00211

nn

0a

mov n3, no

329

0020

Bf

02

mov

St. 12

330

002F

1 7

i nc a

331

0030

ad

- Industrial serial port bluetooth, Drop-in replacement for wired serial connections, transparent usage. You can use it simply for a serial port replacement to establish connection between MCU and GPS, PC to your embedded project and etc. Computer and peripheral devices.

- Running in slave role: Pair with BT dongle and master module.

- Allows your device to both send or receive the TTL data via Bluetooth technology without connecting a serial cable to your computer..

- Default serail port setting : 9600 1 Pairing code : 1234.

- Module working voltage 3.3V to 6V.

- ›See more product details.

What’s New in the PC OMR 4.7 serial key or number?

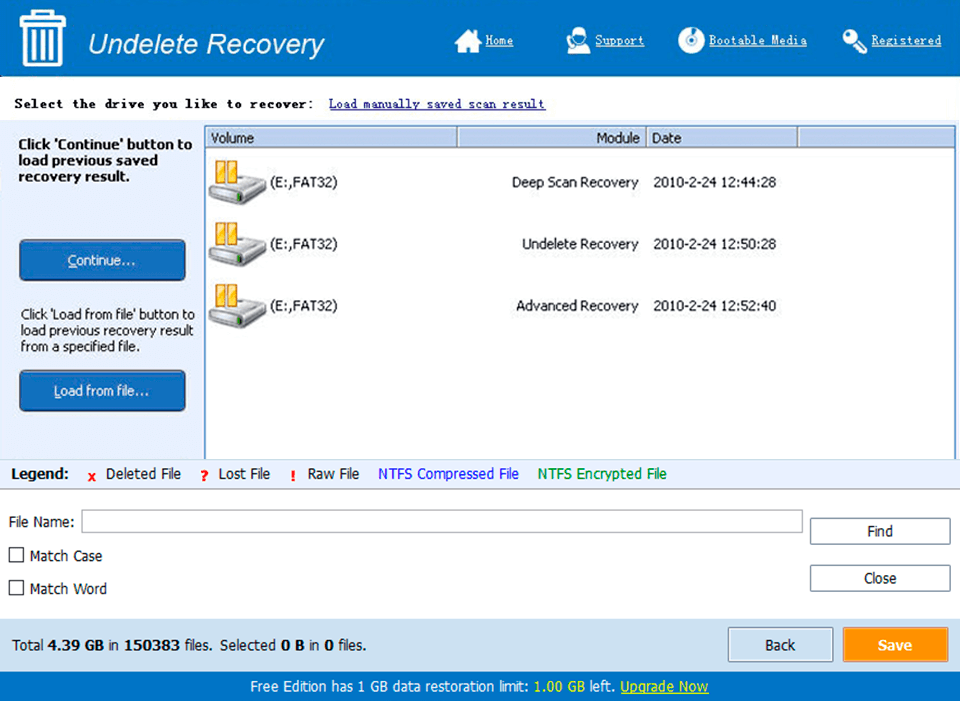

Screen Shot

System Requirements for PC OMR 4.7 serial key or number

- First, download the PC OMR 4.7 serial key or number

-

You can download its setup from given links: