21.08.2019

Garrys mod steam tds serial key or number

Garrys mod steam tds serial key or number

This item has been removed from the community because it violates Steam Community & Content Guidelines. It is only visible to you. If you believe your item has been removed by mistake, please contact Steam Support.

This item is incompatible with Garry's Mod. Please see the instructions page for reasons why this item might not work within Garry's Mod.

Current visibility: Hidden

This item will only be visible to you, admins, and anyone marked as a creator.

Current visibility: Friends-only

This item will only be visible in searches to you, your friends, and admins.

ChokshiUtsav / StackOverFlowTagPredictor

------- SUPPLEMENT FOR PRETREATMENT TO THE DEVELOPMENT DOCUMENT for the STEAM ELECTRIC POWER GENERATING POINT SOURCE CATEGORY Douglas M. Costle Admini strator Andrew W. Breidenbach, Ph.D. Assistant Administrator for Water and Hazardous Materials Eckardt C. Beck Deputy Assistant Administrator for Water Planning and Standards ri Robert B. Schaffer Director, Effluent Guidelines Division John Lum Project Officer April 1977 Effluent Guidelines Division Office of Water and Hazardous Materials U.S. Environmental Protection Agency Washington, D.C. 20460 SB

------- ABSTRACT This document presents the findings of an extensive study of that section of the Steam Electric Power Generating Industry which discharges industrial wastes to publicly owned treatment works (POTW). Its purpose is to develop pretreatment standards to implement section 307 (b) of the Federal Water Pollution Control Act Amendment of 1972 for the Existing Power Plants. Pretreatment standards, recommended in Section II of this report set forth the degree of effluent reduction achievable through the application of control technology currently available for those pollutants which are determined not to be susceptible to treatment by a POTW or which would interfere with the operation of such works. These pretreatment standards set forth the degree of effluent reduction achievable through application of the available demonstrated control technology, processes, operating methods, or other alternatives. These standards must be achieved no later than three (3) years from the date of promulgation. Supporting data and rationale for development of pretreat- ment standards are contained in this report. iii

------- LIST OF CONTENTS Page ABSTRACT iii TABLE OF CONTENTS V LIST OF FIGURES ix LIST OF TABLES xi I. CONCLUSIONS 1 II. RECOMMENDATIONS 3 III. INTRODUCTION 9 General Background 9 Purpose and Authority 10 Scope of Work and Technical Approach 10 General Description of the Industry 13 Process Description 13 Publicly-Owned Treatment Works (POTW) 22 IV. INDUSTRY CATEGORIZATION 25 Introduction 25 Industry Categorization 25 Factors Considered 25 Age 25 Size 26 Fuel 26 Geography 26 Mode of Operation 28 Raw Water Quality 28 Volume of Water Used 28 Pretreatment Technology 28 V. WATER USE AND WASTE CHARACTERIZATION 29

------- Introduction 29 Principles of Operation of steam Electric Power Plant 29 Water Use and Waste characterization by Category 32 Condenser Cooling Water 34 Water Treatment 42 Demineralizer Regenerant Wastes 47 Boiler Slowdown 49 Maintenance Cleaning 53 Ash Handling Systems 58 Air Pollution Control Equipment 65 The POTW Process 70 Flows of POTW Receiving Steam Electric Wastewaters 77 VI. CONSIDERATION OF POLLUTANT PARAMETERS 85 Introduction 85 The Consideration of Pollutant Parameters 85 Properties of Pollutant Parameters Considered 86 VII. TREATMENT AND CONTROL TECHNOLOGY 105 Introduction 105 End-of-Pipe Treatment Technology 105 Treatment of Major Pollutants 106 End-of-Pipe Technology for Major Waste Streams 114 Water Management 120 In-Plant Control Techniques 121 vi

------- Material Substitution 121 Water Conservation and Wastewater Reuse 125 VIII. COST, ENERGY AND OTHER NON WATER QUALITY ASPECTS 129 Introduction 129 Cost Reference and Rationale 130 Costs for Pretreatment 133 Levels of Pretreatment 131 Cost Estimates 1UU Ultimate Disposal 151 Energy Considerations 155 IX. BEST PRACTICABLE PRETREATMENT TECHNOLOGY 157 X. ACKNOWLEDGEMENTS 163 XI. REFERENCES 165 XII. GLOSSARY 168 APPENDIX A - STATISTICAL ANALYSIS OF HISTORICAL DATA 179 APPENDIX B - WATER GLOSSARY 221 APPENDIX C - METRIC UNITS CONVERSION TABLE 253 VII

------- VIII-1 Model Waste Pretreatment Plant - 25 MW Generating Facility 143 VIII-2 Model Waste Pretreatment Plant - 500 MW Generating Facility 146 VIII-3 Cooling Water System Slowdown Treatment for Level D Pretreatment 153

------- SECTION I CONCLUSION An engineering evaluation of steam electric power generating plants that discharge all or a portion of their aqueous wastes to publicly-owned treatment works (POTW) was conducted to establish the basis for pretreatment standards. For the purpose of establishing such standards it was deemed practical to divide the wastes from power plants into the following waste-types: o Condenser Cooling System o Boiler Water Treatment o Boiler Slowdown o Maintenance Cleaning o Ash Handling o Drainage o Air Pollution Control Devices o Miscellaneous Waste Streams This division is identical to that presented in the development document for direct dischargers (14) in this industry with the deletion of Construction Activity. This division was found to be valid as examination of process characteristics and raw wastes were not found to be significantly different from those of direct dischargers. Conduct of the work involved contact with 49 steam electric power generating stations, representing 50 percent of the estimated 98 stations discharging chemicals wastes to a POTW. Engineering visits and data collection were made to 23 stations. Sampling of raw and pretreated wastes was obtained from eight (8) stations. Additionally, prior work conducted by the EPA, data collected in response to NPDES and local discharge permit monitoring, industrial effluent data, and relevant literature prepared by the EPA and electrical trade journals were evaluated. Based on the above evaluation, the following conclusions were reached: o Pollutants discharged by the population of plants discharging to the POTW are similar to those of direct dischargers. o The division of waste types developed above is valid for the purpose of characterizing the waste sources.

------- o Treatment technologies described in the development document for the effluent limitations guidelines for this industry are also applicable to plants discharging to the POTW. A survey of current industry practices has indicated that most plants provide little pretreatment of chemical type wastes at the present time. Based upon information provided in this document regarding pollutant properties and raw waste characteristics, it is determined that some of the pollutants discharged by the Steam Electric Power Generating Point Source Category will interfere with or be treated inadequately by Publicly Owned Treatment Works (POTW).

------- SECTION II RECOMMENDATIONS As a result of the findings and conclusions contained in this report, the pretreatment standards for existing power plants in compliance with the mandates of the Federal Water Pollution Control Act Amendment of 1972 are summarized below: General Unit Subcategory* For the purpose of establishing pretreatment standards under Section 307 (b) of the Act for a source within the General Unit subcategory, the provisions of 40 CFR 128 shall not apply. The pretreatment standards for an existing source within the general unit subcategory are set forth below. (a) No pollutant (or pollutant property) introduced into a publicly owned treatment works shall interfere with the operation or performance of the works. Specifically, the following wastes shall not be introduced into the publicly owned treatment works: (1) Pollutants which create a fire or explosion hazard in the publicly owned treatment works. (2) Pollutants which will cause corrosive structural damage to treatment works, but in no case pollutants with a pH lower than 5.0, unless the works is designed to accommodate such pollutants. (3) Solid or viscous pollutants in amounts which would cause obstruction to the flow in sewers, or other interference with the proper operation of the publicly owned treatment works. (4) Pollutants at either a hydraulic flow rate or pollutant flow rate which is excessive over relatively short time periods so that there is a treatment process upset and subsequent loss of treatment efficiency. (b) In addition to the general prohibitions set forth in paragraph (a) above, the following pretreatment standard establishes the quality or quantity of pollutants or pollutant properties controlled by this section which may be introduced into a publicly owned treatment works by a source subject to the provisions of this subpart.

------- (1) There shall be no discharge to publicly owned treatment works of polychlorinated biphenol compounds such as those used for tranformer fluid. (2) The quantity of copper discharged in metal cleaning wastes to publicly owned treatment works shall not exceed the quantity determined by mulitplying the flow of metal cleaning wastes times 1 mg/1. (3) The quantity of oil and grease in the plant*s combined discharge to the publicly owned treatment works shall not exceed the quantity determined by multiplying the flow of the combined discharge times 100 mg/1. (c) Any owner or operator of any source to which the pretreatment standards required by paragraph (a) above are applicable, shall be in compliance with such standards upon the effective date of such standards. The time for compliance with standards required by paragraph (b) above shall be within the shortest time but not later than three years from the effective date of such standards. Small Unit Subcategory* For the purpose of establishing pretreatment standards under Section 307 (b) of the Act for a source within the Small Unit subcategory, the provisions of UO CFR 128 shall not apply. The pretreatment standards for an existing source within the small unit subcategory are set forth below. (a) No pollutant (or pollutant property) introduced into a publicly owned treatment works shall interfere with the operation or performance of the works. Specifically, the following wastes shall not be introduced into the publicly owned treatment works: (1) Pollutants which create a fire or explosion hazard in the publicly owned treatment works. (2) Pollutants which will cause corrosive structural damage to treatment works, but in no case pollutants with a pH lower than 5.0, unless the works is designed to accommodate such pollutants. (3) Solid or viscous pollutants in amounts which would cause obstruction to the flow in sewers, or other interference with the proper operation of the publicly owned treatment works. (4) Pollutants at either a hydraulic flow rate or pollutant flow rate which is excessive over relatively short

------- time periods so that there is a treatment process upset and subsequent loss of treatment efficiency. (b) In addition to the general prohibitions set forth in paragraph (a) above, the following pretreatment standard establishes the quality or quantity of pollutants or pollutant properties controlled by this section which may be introduced into a publicly owned treatment works by a source subject to the provisions of this subpart. (1) There shall be no discharge to publicly owned treatment works of polychlorinated biphenol compounds such as those used for tranformer fluid. (2) The quantity of copper discharged in metal cleaning wastes to publicly owned treatment works shall not exceed the quantity determined by mulitplying the flow of metal cleaning wastes times 1 mg/1. (3) The quantity of oil and grease in the plant's combined discharge to the publicly owned treatment works shall not exceed the quantity determined by multiplying the flow of the combined discharge times 100 mg/1. (c) Any owner or operator of any source to which the pretreatment standards required by paragraph (a) above are applicable, shall be in compliance with such standards upon the effective date of such standards. The time for compliance with standards required by paragraph (b) above shall be within the shortest time but not later than three years from the effective date of such standards, Old Unit Subcategory* For the purpose of establishing pretreatment standards under Section 307 (b) of the Act for a source within the Old Unit subcategory, the provisions of 40 CFR 128 shall not apply. The pretreatment standards for an existing source within the old unit subcategory are set forth below. (a) No pollutant (or pollutant property) introduced into a publicly owned treatment works shall interfere with the operation or performance of the works. Specifically, the following wastes shall not be introduced into the publicly owned treatment works: (1) Pollutants which create a fire or explosion hazard in the publicly owned treatment works. (2) Pollutants which will cause corrosive structural damage to treatment works, but in no case pollutants with a pH lower than 5»0, unless the works is designed to accommodate such pollutants.

------- (3) Solid or viscous pollutants in amounts which would cause obstruction to the flow in sewers, or other interference with the proper operation of the publicly owned treatment works. Pollutants at either a hydraulic flow rate or pollutant flow rate which is excessive over relatively short time periods so that there is a treatment process upset and subsequent loss of treatment efficiency. (b) In addition to the general prohibitions set forth in paragraph (a) above, the following pretreatment standard establishes the quality or quantity of pollutants or pollutant properties controlled by this section which may be introduced into a publicly owned treatment works by a source subject to the provisions of this subpart. (1) There shall be no discharge to publicly owned treatment works of polychlorinated bi phenol compounds such as those used for tranformer fluid. (2) The quantity of copper discharged in metal cleaning wastes to publicly owned treatment works shall not exceed the quantity determined by mulitplying the flow of metal cleaning wastes times 1 mg/1. (3) The quantity of oil and grease in the plant's combined discharge to the publicly owned treatment works shall not exceed the quantity determined by multiplying the flow of the combined discharge times 100 mg/1. (c) Any owner or operator of any source to which the pretreatment standards required by paragraph (a) above are applicable, shall be in compliance with such standards upon the effective date of such standards. The time for compliance with standards required by paragraph (b) above shall be within the shortest time but not later than three years from the effective date of such standards. Area Runoff Subcategory* For the purpose of establishing pretreatment standards under Section 307 (b) of the Act for a source within the Area Runoff subcategory, the provisions of 40 CFR 128 shall not apply. The pretreatment standards for an existing source within the area runoff subcategory are set forth below. (a) No pollutant (or pollutant property) introduced into a publicly owned treatment works shall interfere with the operation or performance of the works. Specifically, the following wastes shall not be introduced into the publicly owned treatment works:

------- (1) Pollutants which create a fire or explosion hazard in the publicly owned treatment works. (2) Pollutants which will cause corrosive structural damage to treatment works, but in no case pollutants with a pH lower than 5.0, unless the works is designed to accommodate such pollutants. (3) Solid or viscous pollutants in amounts which would cause obstruction to the flow in sewers, or other interference with the proper operation of the publicly owned treatment works. (U) Pollutants at either a hydraulic flow rate or pollutant flow rate which is excessive over relatively short time periods so that there is a treatment process upset and subsequent loss of treatment efficiency. (b) Any owner or operator of any source to which the pretreatment standards required by paragraph (a) above are applicable, shall be in compliance with such standards upon the effective date of such standards. *The definitions of these subcategories are the same as those used for the effluent limitations guidelines regulations.

------- SECTION III INTRODUCTION General Background The involvement of the Federal Government in water pollution control dates back to 1948 when Congress enacted the first comprehensive measure aimed specifically at this problem. At that time the Surgeon General, through the U.S. Public Health Service, was authorized to assist states in various ways to address the problem. The emergence of a national water pollution control program came about with the enactment of the Water Pollution Control Act of 1956 (Public Law 84-660). To date this law remains the basic law governing water pollution. It establishes the basic system of technical and financial assistance to states and municipalities, as well as enforcement procedures by which legal steps can be initiated against polluters. The present program dates back to the Water Quality Act of 1965 and the Clean Water Restoration Act of 1966. Under the 1965 Act, states were required to adopt water quality standards for interstate waters, and to submit to the Federal Government, for approval, plans to implement and enforce these standards. The 1966 Act authorized Federal participation in construction of sewage treatment plants. On amendment, the Water Quality Act of 1970, extended Federal activities into such areas as pollution by oil, hazardous substances, sewage from vessels, and mine drainage. Originally, pollution control activities were the responsibility of the U.S. Public Health Service. In 1961, the Federal Water Pollution Control Administration (FWPCA) was created in the Department of Health, Education and Welfare, and in 1966, the FWPCA was transferred to the Department of the Interior. The name was changed in early 1970 to the Federal Water Quality Administration and in December 1970, the Environmental Protection Agency (EPA) was created by Executive Order as an independent agency outside the Department of the Interior. Executive Order 11574 on December 23, 1970, established the Permit Program, requiring all industries to obtain permits for discharge of wastes into navigable waters or their tributaries under the provisions of the 1899 River and Harbor Act (Refuse Act). The permit program immediately became involved in legal problems resulting in a court ruling that effectively stopped issuance of a significant number of permits. It did result in the filing with EPA, through the U.S. Army Corps of Engineers, of applications for permits which, represent a

------- complete inventory of industrial waste discharges. The granting of a permit under the Refuse Act was dependent on the discharge being able? to meet applicable water quality standards. Although EPA could not specify methods of treatment, they could require minimum effluent levels necessary to meet water quality standards. The Federal Water Pollution Control Act Amendments of 1972 (the "Act") made a number of fundamental changes in the approach to achieving clean water. One of the most significant changes was from a reliance on water quality related effluent limitations to a direct control of effluents through the establishment of technology-based effluent guidelines to form an additional basis, as a minimum, for issuance of discharge permits. The permit program under the 1899 Refuse Act was plciced under full control of EPA, with much of the responsibility to be delegated to the States. PURPOSE AND AUTHORITY Under the Act, the Environmental Protection Agency is charged with establishing pretreatment standards to protect the operation of publicly-owned treatment works and to prevent discharge of pollutants which pass through such works inadequately treated. As part of this Act, Section 307(b) states that the Administrator shall "publish proposed regulations establishing pretreatment standards for introduction of pollutants into treatment works (as defined in Section 212 of this Act) which are publicly owned for those pollutants which are determined not to be susceptible to treatment by such treatment works or which would interfere with the operation of such treatment works. Pretreatment standards under this section shall specify a time for compliance not to exceed three years from the date of promulgation." This report is prepared for the purpose of developing pretreatment standards for existing sources. Pretreatment standards for new sources have been promulgated October of 1974, (together with the effluent limitations guidelines for the Steam Electric Power Generating Point Source Category). SCOPE OF WORK AND TECHNICAL APPROACH The pretreatment standards proposed herein were developed in the following manner. A comprehensive survey was conducted of over 1200 steam electric generating stations in the United States. The stations were screened in two stages: (1) the entire population was screened and cross-matched using available references and (2) 230 stations were 10

------- contacted by telephone. The list of plants that discharge to a POTW was first studied for the purpose of determining whether separate standards would be required for different divisions within the list. The analysis was based upon fuels used, size production process employed, wastewater pretreatment at plant sites, and other factors. The raw waste characteristics for each subcategory were then identified. This included an analyses of (1) the source and volume of water used in the process employed (2) the constituents (including thermal) of all wastewaters including constituents which result in taste, odor, and color in water, (3) the effect of the constituent on the operation of the POTW and (4) the adequacy of the POTW in treatment of such constituents. Wastewaters which should be subject to pretreatment standards were identified. The full range of control and pretreatment technologies existing within each subcategory was identified. This included identification of each distinct control and pretreatment technology, including both in-plant and end-of- process technologies, which are existent or capable of being designed for each division. It also included an identification of the amount of constituents and the chemical, physical, and biological characteristics of pollutants. Effluent levels resulting from the application of each of the pretreatment and control technologies were also identified. The problems, limitations, and reliability of each pretreatment and control technology were also identified. In addition, the nonwater quality environmental impact, such as the effects of the application of such technologies upon other pollution problems, including air, and solid waste, were also identified. The energy requirements of each of the control and treatment technologies were identified as well as the cost of the application of such technologies. The information, as outlined above, was then evaluated in order to determine what levels of technology are available for effluent reduction. In identifying such technologies, various factors were then considered. These included the total cost of application of technology, the age of equipment and facilities involved, the process employed, the engineering aspects of the application of various types of control techniques, process changes, nonwater quality environmental impact (including energy requirements), and other factors. Data for identification and analyses were obtained from a number of sources. These sources included EPA research information; EPA, state, and local environmental personnel; trade associations; published literature; qualified technical consultation; historical information on effluent 11

------- quality and quantity; and on-site visits including analytical programs and interviews at steam electric plants throughout the United States which were known to have above average waste pretreatment facilities. All references used in developing the pretreatm:nt standards reported herein are listed in Section XI of this; document. Twenty-three operating plants were visited and eight were sampled. Composite samples over a sixteen hour period were obtained from these eight plants and were analyzed for parameters mentioned in Section V. Information was obtained from as many as fifteen (15) plants for each waste-type division. Both in-process and end-of-pipe data were obtained as a basis for determining "citer use rates capabilities and effluent loads. Permit application data was of value for the purposes of this study when such data covered outfalls serving only steam electric power operations. Cost information was obtained directly from industry during plant visits, from engineering firms, equipment suppliers, and from the literature. These costs have been used to develop general capital, operating, and total costs for each pretreatment and control method. This generalized cost data and specific information obtained from plant visits was used to estimate cost effectiveness in Section VIII and elsewhere in this report. Certain plants were selected for in-depth analysis from the total population of those visited. These plants were plants discharging representative waste types or employing above average treatment technology or having substantial quantities of historic effluent data. The following selection criteria were developed and used for selection of plants visited and sampled. 1. Representative plant with respect to fuel type, size, geographical location and other factors. 2. Plants that discharge types or quantities of waste representative of those delineated in Section IV. Plants that have treatment, GENERAL DESCRIPTION OF THE INDUSTRY The Steam Electric Power Industry is made up of 1273 plants throughout the contiguous United States. Of these plants an estimated 7.7 percent or 98 plants discharge wastewaters to publicly-owned treatment works and are thus covered by the 12

------- scope of this document. In this study 49 plants discharging to POTW were contacted. Statistics for this section were estimated based on a truly random sampling of steam electric power plants contained in the "Environmental Assessment of Alternative Thermal Control Strategies for the Electric Power Industry" by Michelle M. Zarubica of the Office of Planning and Evaluation of the Environmental Protection Agency (18). Steam Electric plants discharging to the POTW tended to be smaller on the average than plants discharging to surface water. These plants averaged about 150 MW for a total capacity of 14,500 MW which compares with an average capacity and total generating capacity of about 400 MW and 506,700 MW for the entire Steam Electric Industry. (See Tables III-l and III-2). Of these plants, an estimated 72 percent are publicly-owned and 28 percent are investor owned. Most of the Steam Electric plants that discharge to POTW (68 percent) use gas as their principal fuel compared to 31 percent for the entire industry (Figures III-l and III-2). Conversion of some plants from gas to oil is expected due to shortage of natural gas. Plants which discharge wastewaters to POTW tend to have units older than plants which discharge to surface waters. Tables III-l and III-2 show that 29 percent of the plants which discharge to POTW were built since 1960 as compared to 38 percent for the entire population. Also, plants built since 1960 represent 48 percent of the generating capacity of plants discharging to POTW compared to 78 percent for the entire Steam Electric Industry. (See Figures III-3 and III- 4). Approximately 24 percent of all electrical generation is nuclear powered but no plants of this type were observed to discharge to the POTW. Nonetheless, nuclear plants are included in this document, since their chemical waste discharges are similar in nature to those discharged by non- nuclear facilities (14) . Steam Electric plants discharging to POTW are located in all regions of the country with somewhat higher than average concentrations in the Midwest and in California. Process Description The "production" of electrical energy involves utiliation and conversion of chemical or nuclear energy. Present day methods of utilizing energy of fossil fuels are based on a 13

------- Table III-l. TOTAL. STEAM ELECTRIC PLANTS IN THE CONTIGUOUS UNITED STATES Total Number of Plants = 1273 Total Number of Units = 3011 Total Number of Megawatts^ 506,654 Average Station Size = 398 Percentage of Plants Confirmed as Discharging to Municipal Sewers - by Number = 7.7% by Megawatts = 2.9% Principal Percentage by Percentage by Unit Fuel Number Megawatts Gas 31.0 Oil 14.6 Coal 49.3 Nuclear 5.1 100.0 Percentage by Percentage by Unit Built In Number Megawatts 1970's 17.6 57.6 1960's 20.3 20.1 1950's 36.1 17.6 1940's 16.0 3.7 1930's 6.5 0.8 1920's 2.7 0.1 1910's 0.8 0.1 14

------- Table II1-2. STEAM ELECTRIC PLANTS DISCHARGING TO MUNICIPAL SEWERS IN THE CONTIGUOUS UNITED STATES Total Number of Plants = 98 Total Number of Units = 277 Total Number of Megawatts - 14504 Average Station Size = 148 Principal Unit Fuel Gas Oil Coal Nuclear Percentage by Number 67.7 17.7 14.7 0.0 Percentage by Megawatts 44.1 54.0 1.9 0.0 100.0 100.0 Unit Built In 1970's 1960's 1950's 1940's 1930's 1920's 1910's Percentage by Number 5. 23. 35.3 23.5 5.9 5.9 0.0 100.0 Percentage by Megawatts 4.3 43.2 47.0 5.2 0.2 0.1 0.0 100.0 15

------- TOO 90 80 70 OVERALL PLANTS POPULATION DISCHARGING TO POTW'S OO o UJ CJ o: 60 50 40 J 30 20 10 GAS FIGURE III-l OIL PRINCIPAL FUEL COAL NUCLEAR Principal Fuel Use by Number 16

------- 100 90 80 =C CS o LlJ cs Cd UJ a. 70 60 50 40 30 20 10 . . OVERALL PLANTS POPULATION DISCHARGING TO POTW'S GAS OIL PRINCIPAL FUEL COAL NUCLEAR FIGURE III-2. Principal Fuel Use by Megawatts

------- 100 . 90 80 70 OVERALL DISCHARGING POPULATION TO POTW'S CO C_3 o: 60 50 40 30 20 10 1910 1920 1930 1940, 1950 1960 YEAR PLANT BUILT 1970 FIGURE III-3. Year of Construction by Number 18

------- 100 . 90 80 5 70 3

What’s New in the Garrys mod steam tds serial key or number?

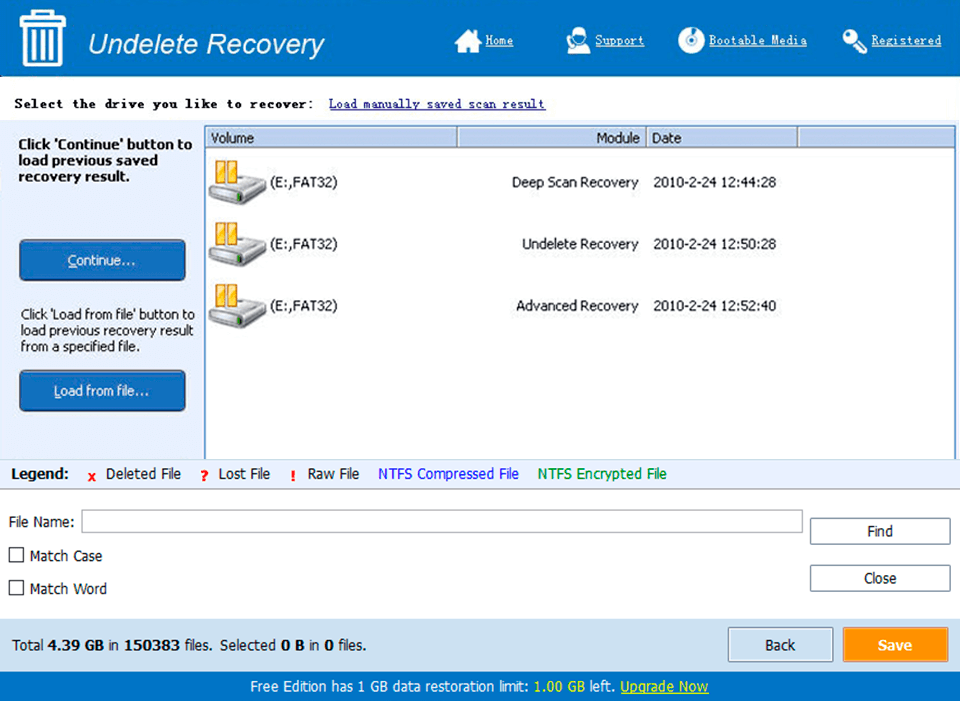

Screen Shot

System Requirements for Garrys mod steam tds serial key or number

- First, download the Garrys mod steam tds serial key or number

-

You can download its setup from given links: